Industrial solutions for monitoring, safety, and real-time operations.

Build a scalable, multi-user software that helps your business monitor factories, machines, and compliance in real time.

About

Zwillio

Digital Twin Platform

Core Modules

The foundation of the Zwillio engine.

Data Integration

Connect your sensors, legacy machines, and enterprise software into one real-time digital stream.

AI & Analytics

Turn data into actions with AI models that learn from your environment.

Multi Level Visibility

Track performance from a single asset to your entire global operation in one clear, customized view.

Response System

Prevent downtime with alerts that notify your team when a threshold is met.

Core Modules

Visualizing your data in action.

Shopfloor Perspective

Gain complete oversight of floor operations with real-time heatmaps and interactive 3D process models.

Workflow Optimization

Analyze end to end production cycles to identify bottlenecks and simulate future operational scenarios.

Asset Health Diagnostics

Access deep dive performance metrics for individual machines to maximize reliability and equipment life.

Core Modules

Visualizing your data in action.

Smart Factory

Gain complete oversight of floor operations with real-time heatmaps and interactive 3D process models.

Process Optimization

Analyze end to end production cycles to identify bottlenecks and simulate future operational scenarios.

Machine Health

Access deep dive performance metrics for individual machines to maximize reliability and equipment life.

Connect your sensors, legacy machines, and enterprise software into one real-time digital stream.

Data Integration

Turn data into actions with AI models that learn from your environment.

AI & Analytics

Prevent downtime with alerts that notify your team when a threshold is met.

Response System

Track performance from a single asset to your entire global operation in one clear, customized view.

Multi-Level Visibility

Core Modules

Data Integration

Connect your sensors, legacy machines, and enterprise software into one real-time digital stream.

Multi-Level Visibility

Track performance from a single asset to your entire global operation in one clear, customized view.

AI & Analytics

Turn data into actions with AI models that learn from your environment.

Response System

Prevent downtime with alerts that notify your team when a threshold is met.

Core Modules

Data Integration

Connect your sensors, legacy machines, and enterprise software into one real-time digital stream.

Multi-Level Visibility

Track performance from a single asset to your entire global operation in one clear, customized view.

AI & Analytics

Turn data into actions with AI models that learn from your environment.

Response System

Prevent downtime with alerts that notify your team when a threshold is met.

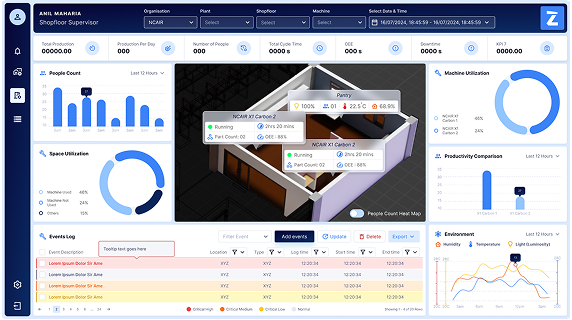

Operational Intelligence

Visualizing your data in action through our Zwillio dashboards

Gain complete oversight of floor operations with real-time heatmaps and interactive 3D process models.

Access deep dive performance metrics for individual machines to maximize reliability and equipment life.

Asset Health Diagnostics

Shopfloor Perspective

Workflow Optimization

Analyze end-to-end production cycles to identify bottlenecks and simulate future operational scenarios.

Operational Intelligence

Visualizing your data in action through our Zwillio dashboards

Shopfloor Perspective

Gain complete oversight of floor operations with real-time heatmaps and interactive 3D process models.

Workflow Optimization

Analyze end-to-end production cycles to identify bottlenecks and simulate future operational scenarios.

Asset Health Diagnostics

Access deep dive performance metrics for individual machines to maximize reliability and equipment life.

Operational Intelligence

Visualizing your data in action through our Zwillio dashboards

Gain complete oversight of floor operations with real-time heatmaps and interactive 3D process models.

Analyze end-to-end production cycles to identify bottlenecks and simulate future operational scenarios.

Access deep dive performance metrics for individual machines to maximize reliability and equipment life.

Benefits for Industries

Purpose built solutions for high-stakes industries.

Directive Maintenance

Predictions to provide the maintenance sequence required to protect heavy haul fleet.

TreadZ

Smart Tire Intelligence

Real time health tracking for heavy haul tires to prevent blowouts and reduce replacement costs.

Features

The measurable impact for your enterprises.

Lower Production Costs

Downtime Reduction

Safety & Compliance

System Resilience

Scrap Reduction

Increased Quality

Lower Utility Consumption

Lower Carbon Footprint

Who can benefit?

Our solution can help factory floor engineers and technicians, maintenance teams, reliability engineers, and line supervisors who need real-time visibility, as well as process/quality engineers who want to optimise parameters and minimize variation with predictive intelligence and closed-loop control. Manufacturing companies with production lines, heavy machinery, and multi-workshop plants (in automotive, heavy equipment, tyre, machine tools, etc) can deploy our solutions seamlessly.

Industries we serve

Purpose built solutions for high-stakes industries.

MinePulse

Predictions to provide the maintenance sequence required to protect heavy haul fleet.

How it Works

From data to decisions in four steps, our integrated platform transforms your physical operations into intelligent digital systems

Data

Collection

Specialized hardware collects real-time data from your physical assets and environments

Processing

& Analysis

Advanced AI algorithms process and analyze data streams in real-time

Digital Twin Creation

Creates accurate virtual replicas of your physical systems with live synchronization

Actionable

Insights

Receive predictive alerts, recommendations, and automated responses

Technical Approach

How we built Zwillio

Platform-independent, open-source foundation to ensure total data ownership

High-performance data engine built to handle volumes of industrial time series data with low latency.

Secure deployment across on premise servers, local edge environments, or private cloud architectures.

Features in-house hardware and firmware

using vibration, pressure, temperature and other

sensors for capturing high-frequency data

Operational Efficiency

By optimizing workflows and identifying bottlenecks early, we help your team Improve productivity and reduce downtime

Reliable & Scalable

Our software ecosystem is designed to scale across multiple sites, teams, and geographies, ensuring consistent performance.

Enhanced Safety

Monitor safety and security processes in real time to reduce operational risk, while protecting your assets and personnel.

Actionable Data

Transform raw, centralized data into AI-driven planning, providing predictive maintenance to achieve long-term goals.

Why Choose Us

Experience the advantages of digital twin technology designed for reliability, security, and performance at scale

Real-time monitoring of legacy machines with no digital footprint

Supports multiple communication protocols (Modbus, OPC-UA, MQTT, APIs, etc.)

Single platform to monitor and manage all systems with realtime customisable alerts

Role-based access for managers, engineers, and operators

AI models fine-tuned on customer data for higher accuracy

Platform-independent & open-source foundation

PostgreSQL + TimescaleDB for large-scale time-series data

Docker-based architecture for scalability and easy deployment

Supports on-premise and local server hosting

In-house hardware and firmware for sensors like temperature, pressure, vibration, and current

Technical Approach

The technology approach that Zwillio follows

Platform platform-independent, open-source foundation to ensure total data ownership

High-performance data engine built to handle volumes of industrial time series data with low latency.

Secure deployment across on premise servers, local edge environments, or private cloud architectures.

Features in-house hardware and firmware for sensors like temperature, pressure, vibration, and current